Current projects

- SAGE - Smart actuator for green energies

Efficiency tests and damage detection on highly stressed worm gears in actuators - Remanufacturing Gearboxes of Passenger Cars

Reliability prognosis based on knowledge gained from remanufacturing

Completed projects

- Lifetime Extension of Pittings

Increasing the remaining useful life of gears through an adaptive operating strategy

Project archive

Martin Diesch, IMA

Kroner Andreas, IMA

Stefan Jetter, Daimler AG

A method is being developed for the design of cylinder blocks which makes it possible to provide information on the reliability of cylinder blocks at an early stage of development. The calculation is based on load collectives from driving operation and experimentally determined material data. By linking and comparing calculation and field analysis, a consistent strategy for reliability analysis is to be developed.

Benjamin Heumesser, IMA

Zeljana Beslic, IMA

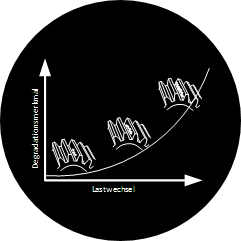

The gear life of a series toothing is to be investigated experimentally on the load test bench for the failure of pittings. A statistical life verification of the gear with regard to the fatigue damage and the influence on the scatter of the degradation model dimples, under the influence of the load, is to be presented. A test methodology with regard to resource planning and a simulation approach are to be verified with the measured data.

Sabine Sanzenbacher, IMA

Gear teeth cause all components of a gear to vibrate due to various mechanisms such as variable tooth stiffness, deviations of the tooth flank geometry from an ideal involute, and impact processes. The resulting noises are known as gear whine and whistling, or as gear rattle and clatter. These noises reach the human ear via direct airborne sound radiation from the housing, or are transmitted as structure-borne sound to add-on parts, which then also radiate these vibrations as airborne sound.

Contact Head of Drive Train Diagnostics and Prognostics

Martin Dazer

PD Dr.-Ing.Head of Department

Lukas Merkle

M.Sc.Vice Head of Department