Test benches

Test benches for rotary seals

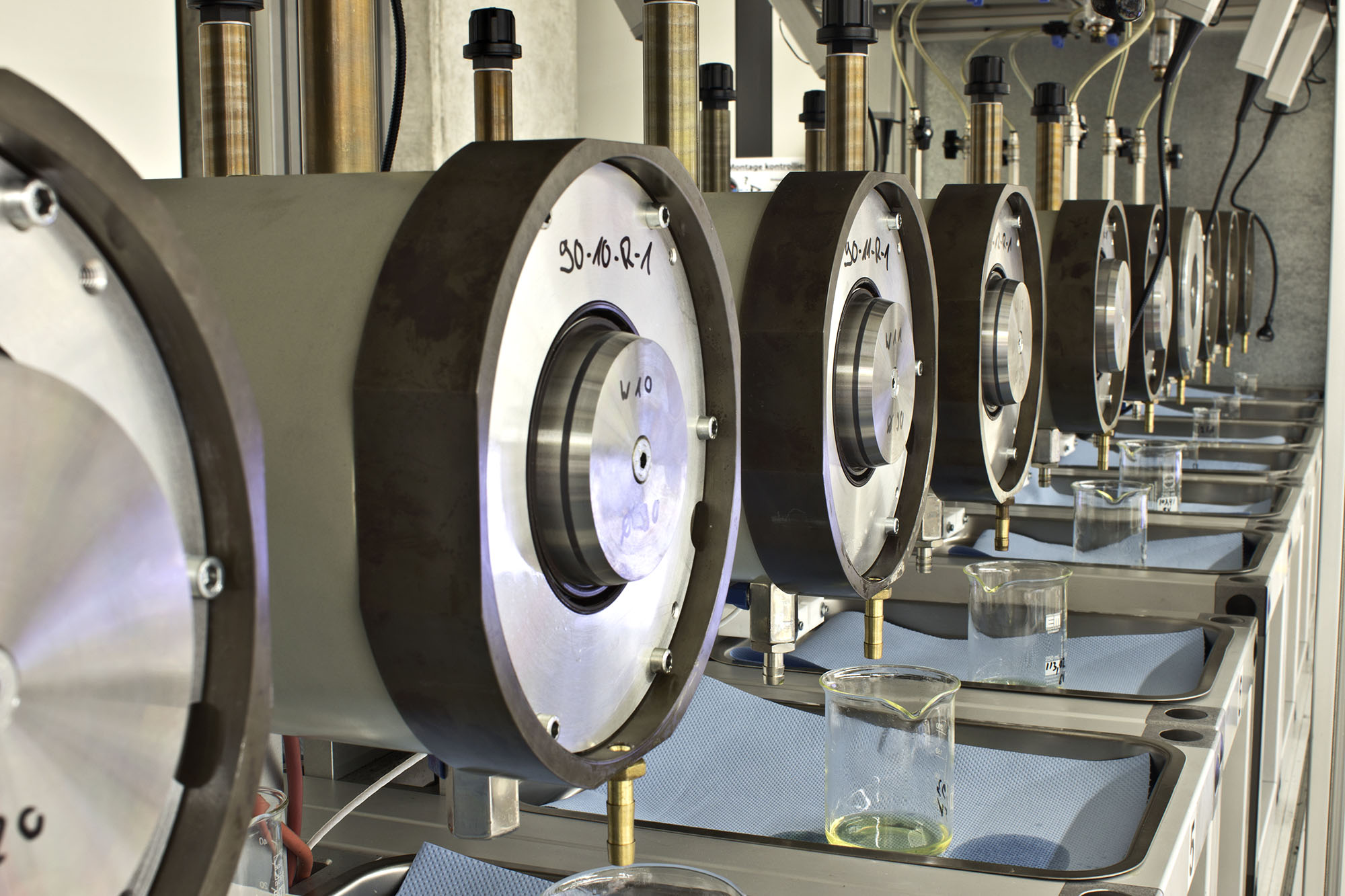

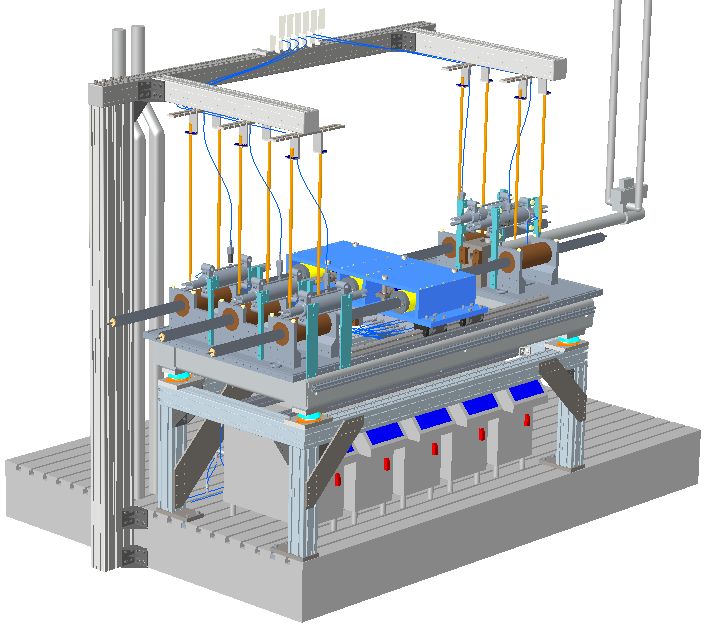

The endurance test benches are constructed differently in order to be able to meet all the requirements for testing sealing systems. For example, there are versions with direct drive for quick changes of direction of rotation or acceleration of the shaft. In addition, individual test stations are equipped with hydraulic power packs to be able to apply high pressures. In addition, there are various designs to be able to operate the seal with oil sump, fluid spraying or even in dry running. In this way, even unusual operating conditions can be realised by means of testing.

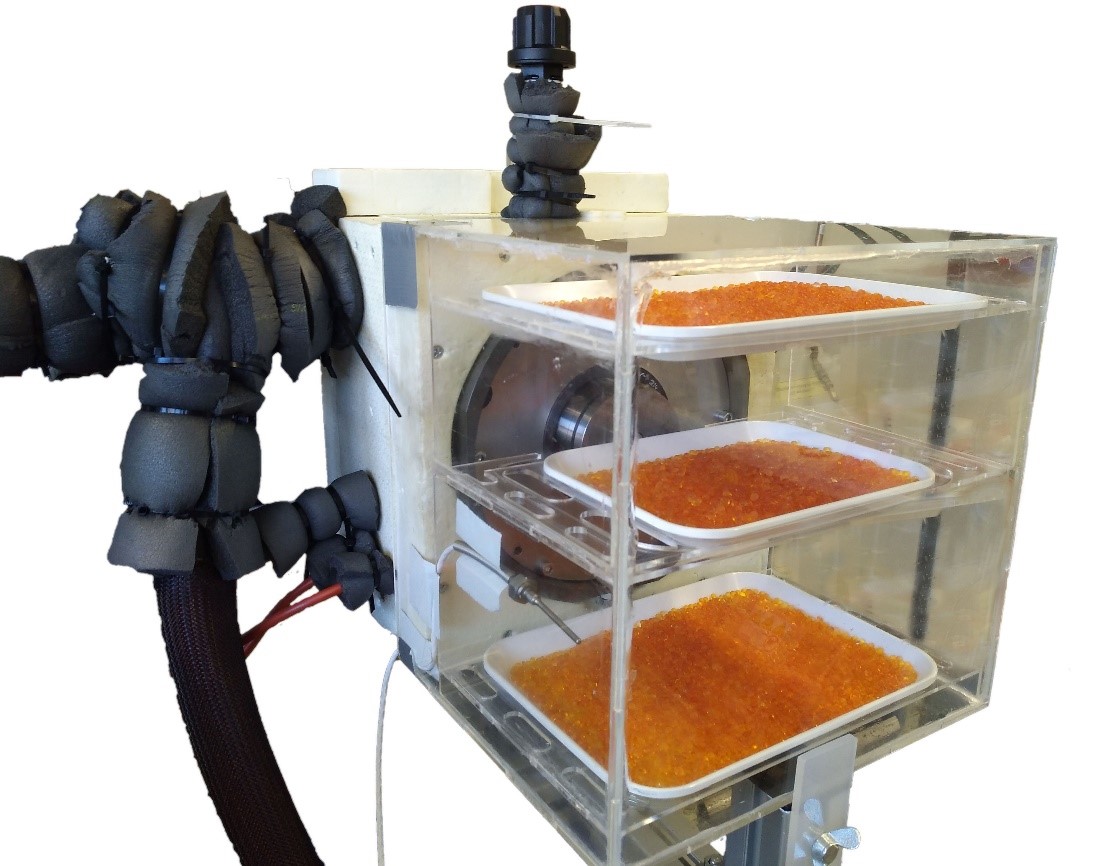

The multi-cell endurance test benches for rotary shaft seals can be modified for special applications. For example, the use of secondary chambers enables the testing of rotary shaft seals in double and multiple arrangements. Just like the test chambers of the test rig, the secondary chambers can be flooded with oil, tempered and pressurized. The oil sump temperature and the pressure in the secondary chamber are monitored by sensors and recorded. Secondary chambers and other test stand extensions are designed and constructed according to the application and manufactured in the institute's own workshop with a short response time.

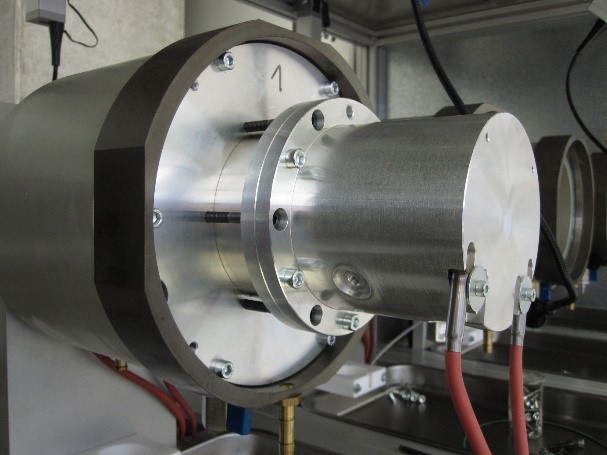

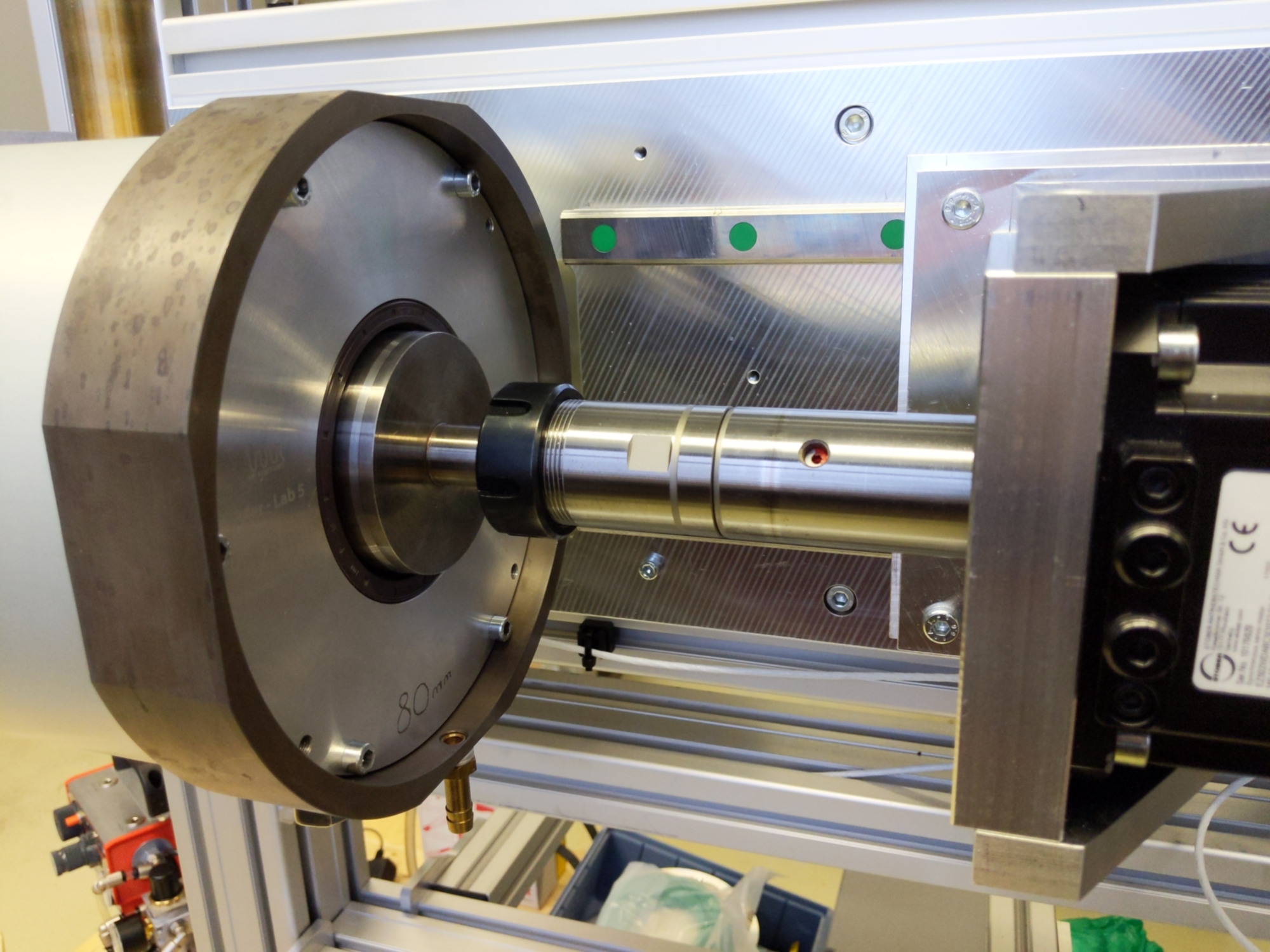

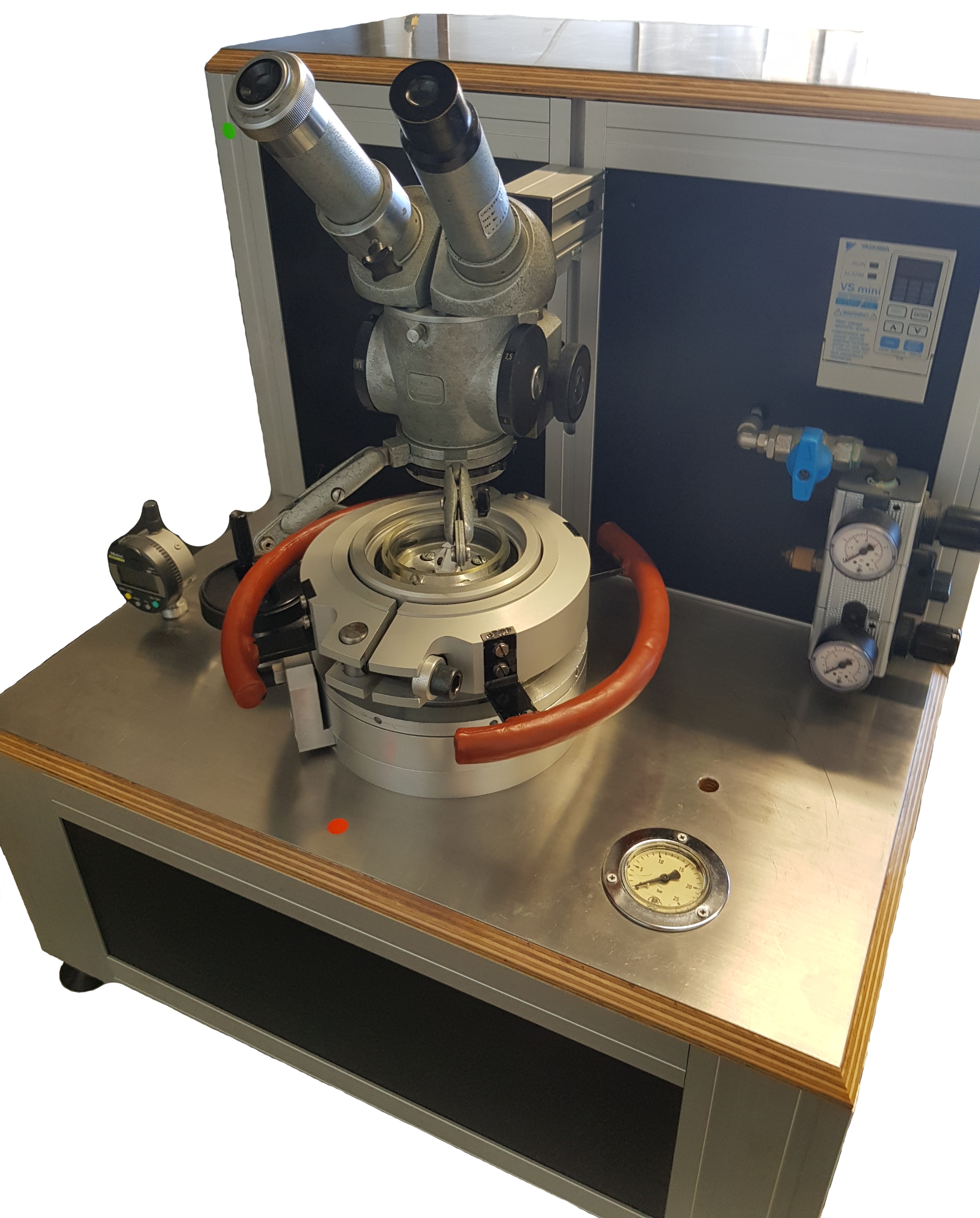

The universal test benches at the IMA are characterized by an extremely high adaptability. A wide range of sealing systems can be investigated by means of specific mounting adapters. A spraying with fluid as well as the tempering of the sealing system can be realized by corresponding aggregates and devices depending on the desired purpose of the examination. Aerostatic bearings allow high-precision friction torque measurements.

The high-speed test stand is characterised by high flexibility and a wide range of measuring and testing possibilities. Tests can be performed at extreme temperatures and high speeds. Even PTFE sleeves can be tested up to their application limits. Due to the aerostatic mounted test chamber an exact measurement of the frictional torque is possible.

The low temperature test rig was specially designed to carry out tests on sealing systems at low temperatures. The operation with fluid sump is possible. This is indirectly tempered via the housing. A powerful low-temperature unit with special coolant is available for this purpose. The operation can be carried out with or without icing of the sealing from the outside.

The water endurance test bench was designed to carry out tests on sealing systems with water or aggressive or corrosive fluids to be sealed. Operation is possible with fluid sump or with fluid spraying. The test stand is designed with a direct drive to ensure fast acceleration and change of direction of rotation. In addition, fluid temperature control and pressurisation of the sealing system is possible.

The water endurance test bench was designed to carry out tests on sealing systems with water or aggressive or corrosive fluids to be sealed. Operation is possible with fluid sump or with fluid spraying. The test stand is designed with a direct drive to ensure fast acceleration and change of direction of rotation. In addition, fluid temperature control and pressurisation of the sealing system is possible.

An optical test rig is used to visually examine the flow under the sealing edge. A hollow glass shaft and a rotatable sealing ring holder as well as an axially movable optical system with a digital video camera form an innovative examination system. This allows the flow in the sealing contact to be observed and analyzed under a wide range of conditions.

An optical test rig is used to visually examine the flow under the sealing edge. A hollow glass shaft and a rotatable sealing ring holder as well as an axially movable optical system with a digital video camera form an innovative examination system. This allows the flow in the sealing contact to be observed and analyzed under a wide range of conditions.

Test benches for translational seals

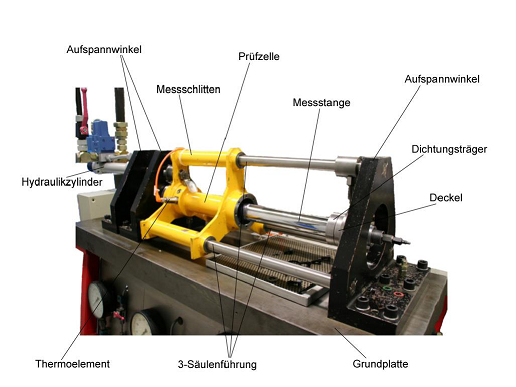

Leakage, wear and pumping rate of a seal/rod combination are examined on the leakage test bench. The application limits are 35 MPa pressure and 1 m/s travel speed. A total of 10 seals can be tested simultaneously. The fixtures are compatible with those of the friction force test rig. Thus, sealing rings can be examined on both test benches.

The friction force of hydraulic rod seals can be measured with the friction force test bench, separately for retracting and extending stroke. Tests up to 35 MPa pressure and speeds up to 1 m/s are possible.

The friction force of hydraulic rod seals can be measured with the friction force test bench, separately for retracting and extending stroke. Tests up to 35 MPa pressure and speeds up to 1 m/s are possible.

Today, housing joints are often statically sealed by means of bonded joints. High forces and excitation frequencies are required to investigate the load capacity of such sealing points with respect to oscillating shear and axial forces. These can be realized with the aid of the hydropulser.

Today, housing joints are often statically sealed by means of bonded joints. High forces and excitation frequencies are required to investigate the load capacity of such sealing points with respect to oscillating shear and axial forces. These can be realized with the aid of the hydropulser.

Measuring devices

Surface measuring devices

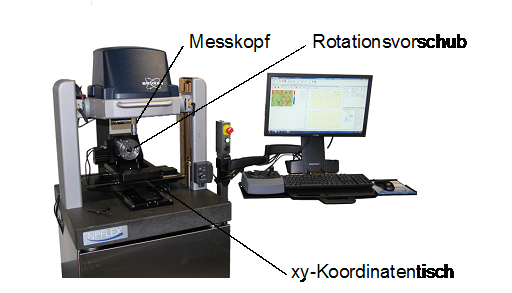

The Confovis surface and lead measuring device is an optical confocal topography measuring system specially developed for applications in sealing technology, with which technical surfaces can be measured with high resolution. Part of the equipment is a rotation unit, which makes it possible to optimally measure rotationally symmetrical shaft sealing surfaces. The Lead-Inspect software module is optimally adapted to sealing technology and, in addition to macro and micro-lead measurement, also enables the measurement of 2D and 3D surface parameters.

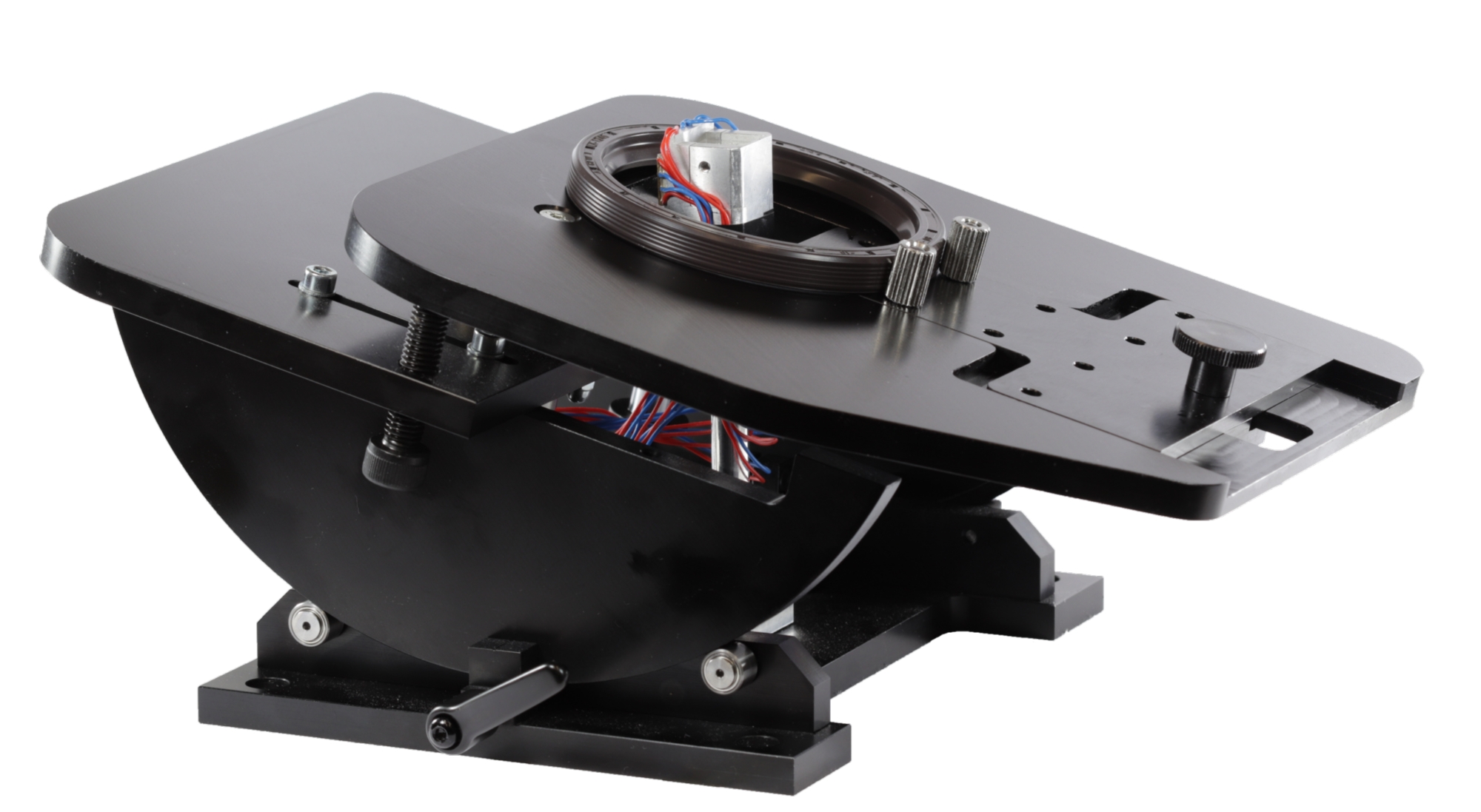

Due to the high measuring speed, white-light interferometry enables particularly large measuring ranges to be measured with high resolution and in short times. With the additional rotation unit, the Bruker NPFLEX - LA is ideal for measuring cylindrical samples and thus ideally equipped for applications in sealing technology.

High resolution 3D images of the seal countersurface and the seal itself can be obtained using the Keyence VK-9710 Laser Scanning Colour Microscope. The detailed view allows views that were previously only possible with scanning electron microscopes.

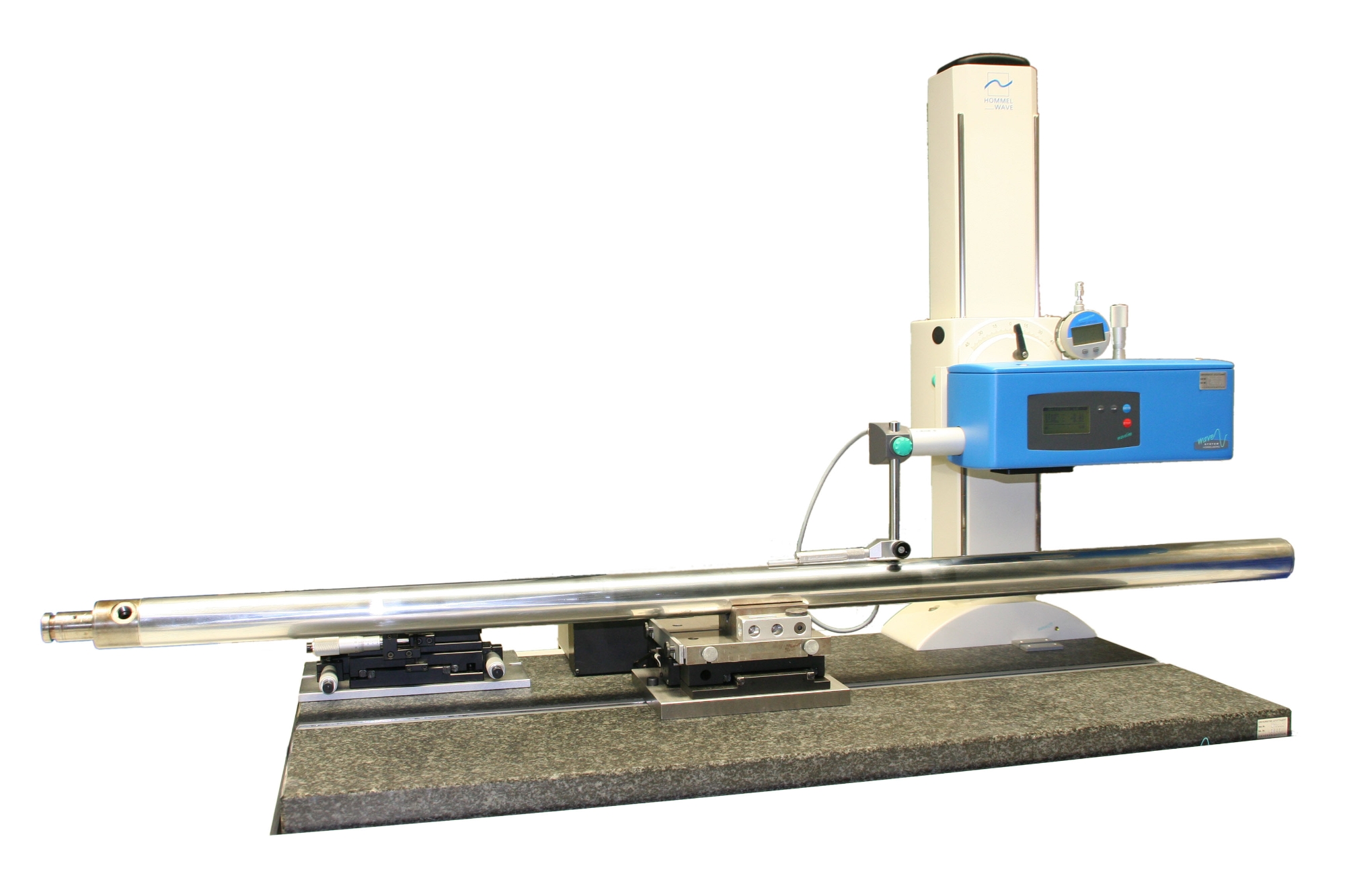

The HOMMEL T8000 roughness measuring device is used to measure roughness and contour profiles of sealing components in accordance with DIN standards.

Measuring instruments for damage analysis and material testing

The IMA-Sealscanner® is a measuring device developed at IMA with which the width of wear of the sealing edge and the inner diameter of a spring-preloaded elastomer radial shaft seal without hydrodynamic return structures can be automatically measured and evaluated. This enables a user-independent, fast and reproducible evaluation of RWDR after test section investigations.

Dynamic sealing systems fail due to a wide variety of damage mechanisms. A distinction can be made between mechanical, thermal and chemical damage. In order to determine the causes of sealing system failures, damage analysis is essential. The IMA Sealobserver allows visual surface analysis of sealing rings using a digital microscope. Variable adjustment options guarantee an optimal view of the sealing edge.

Die Anpresskraft eines Dichtrings hat großen Einfluss auf das Reib- und Abdichtverhalten. Deshalb ist es unumgänglich, die Radialkraft eines Dichtrings exakt zu messen. Am IMA stehen hierfür drei Radialkraftmessgeräte nach DIN 3761-9 zur Verfügung, mit denen die Radialkräfte von fast allen Dichtringtypen auf Wunsch temperiert und wegkompensiert bestimmt werden können.

The hardness of the sealing ring in the contact zone can provide information about chemical or thermal changes caused by operation. At the IMA, the modular hardness tester "Bareiss digi test II" is available for hardness testing of elastomers. In addition to hardness measurements of the sealing edge of radial shaft seals (following the IRHD M method according to DIN ISO 48), standardized measurements on other geometries can also be performed with this instrument.

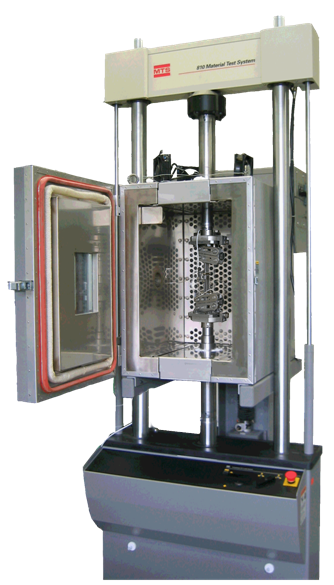

A universal testing machine is available for determining material parameters and, for example, to measure frictional or breakaway forces on axially moving sealing elements. Tensile forces up to 10 kN and various measuring programs with variable movement speeds can be realized. Elongation is measured without contact by a video extensometer. Measurements up to a temperature of 150°C can be carried out by a temperature chamber.

With a 3D deformation-measuring device, component deformations with high dynamics can measure three-dimensionally. For example, dynamically loaded static sealing locations on flanges and housings can be visualized and the deformations that occur can be measured.

Measuring the temperature at the sealing edge has always been a challenge. A contacting measurement during the test runs is not possible. Therefore, two thermographic cameras are available at the institute. A special feature here is the precision microscope lens, which can measure a field of view of 6 x 6 mm with a resolution of 25 μm. However, radiation pyrometers can also be used for this purpose during test bench runs.

Processes in dynamically highly stressed sealing systems can no longer be recorded with the human eye. Therefore, a high-speed camera is used to observe these processes. With this camera, complex flows, stick-slip effects or dynamic start-up processes can be made visible.

The fundamental observation of tribological states is often difficult on real components. For this reason, simplified specimens are analyzed with the help of the rotary tribometers. Friction torque, temperature and wear are measured under variation of the counter surfaces, operating parameters (contact pressure, speed) and lubricants (greases, oils). In addition to the ring-disc principle on the two rotary tribometers, the rheometer can also be operated on the ball-on-three-plate principle.

The fundamental observation of tribological states is often difficult on real components. For this reason, simplified specimens are analyzed with the help of the rotary tribometers. Friction torque, temperature and wear are measured under variation of the counter surfaces, operating parameters (contact pressure, speed) and lubricants (greases, oils). In addition to the ring-disc principle on the two rotary tribometers, the rheometer can also be operated on the ball-on-three-plate principle.

The viscosity of lubricants has a significant influence on the frictional condition of sealing systems and therefore also on possible mechanical wear or thermal damage to the sealing ring. The rheometer MCR 302 from Anton Paar not only allows the viscosity of different lubricants to be measured at different temperatures and shear rates, but also the linear viscoelastic behaviour of the lubricant to be analysed. In addition, normal forces of up to 50 N can be specifically applied and measured via an axial drive.

The contact width of a sealing ring is measured on the circumference of the mounted sealing ring using special measuring instruments. It is even possible to apply pressure up to 25 bar.

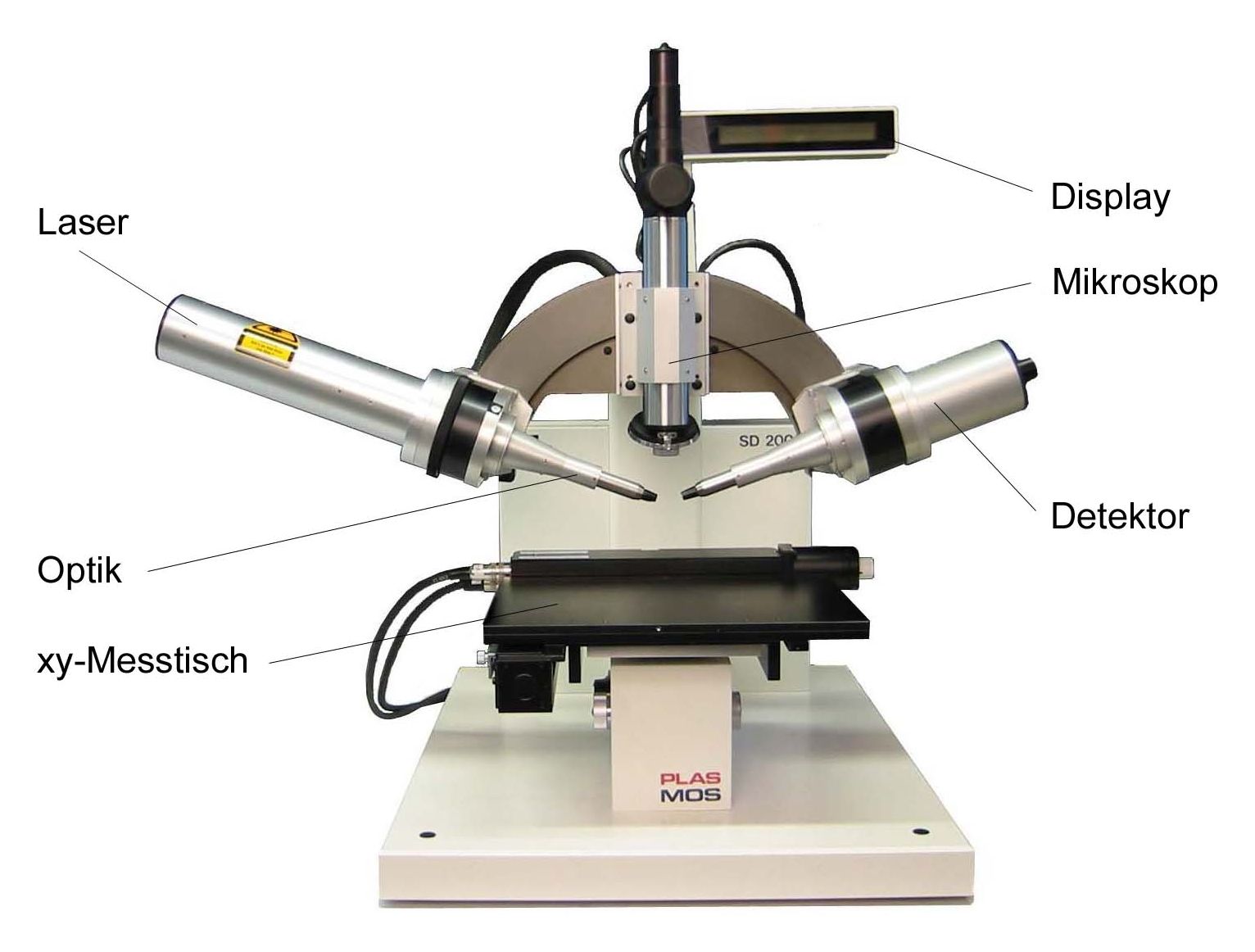

The ellipsometer is a measurement device for the analysis of oil films on hydraulic rods. It is an optical and contactless measurement device. By direct measurement of the oil film thickness from the outstroke and instroke the difference can be calculated. Then, conclusions on the leak tightness can be drawn. The highest resolution of the measurement device is 0.1 nm.

The Phenom ProX is an electron microscope (SEM) with fully integrated microanalysis (EDX). With the Phenom ProX samples can be examined for their morphological properties and chemical element compositions. This allows an observation of the sealing edge with high resolution and high magnification.

Physical measuring devices (surface energy and wetting)

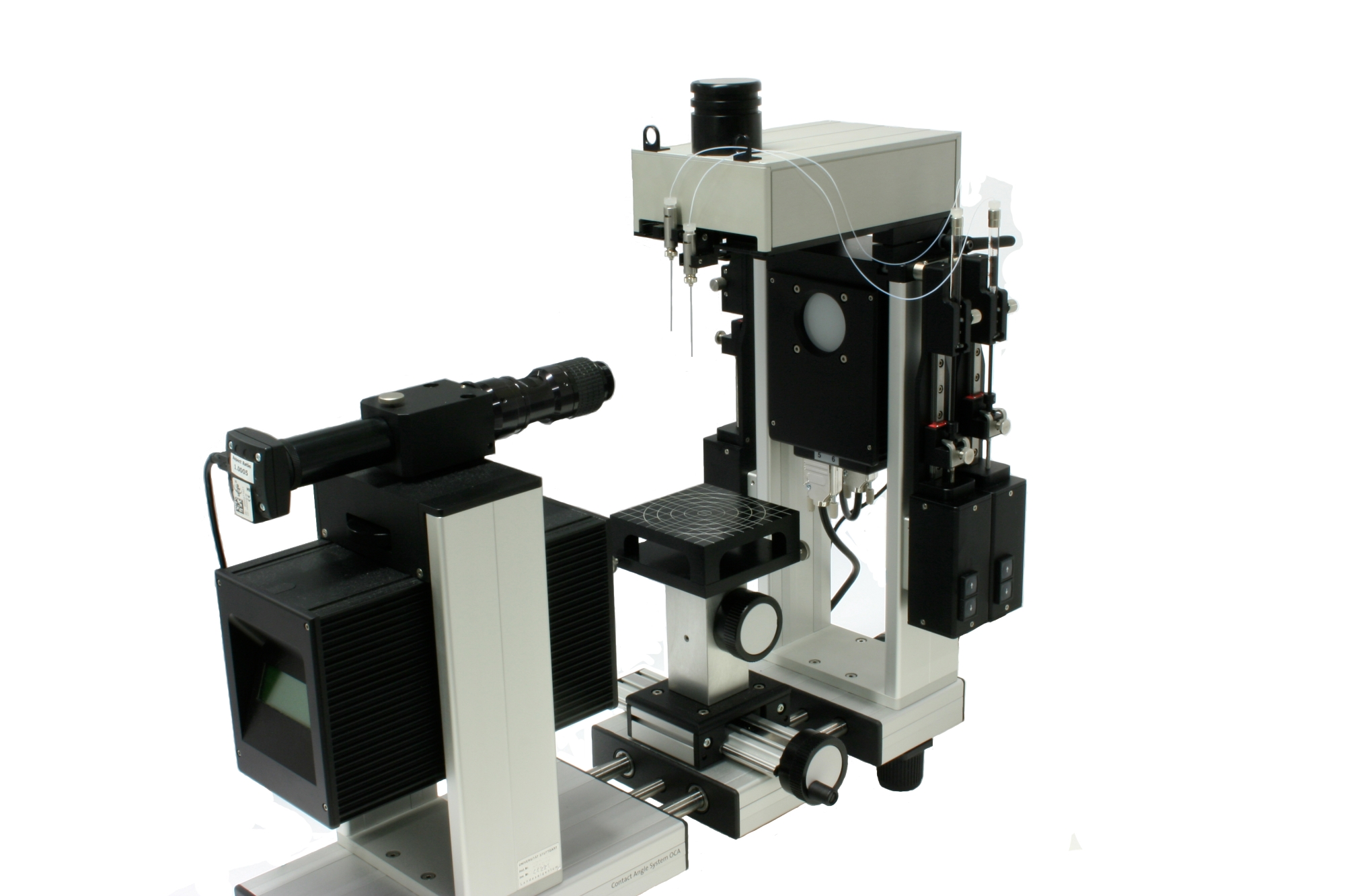

The OCA 20 contact angle meter from dataphysics is a measuring system that can be used to determine wetting properties such as the surface tensions of solids and fluids. The wetting properties of the individual sealing components can be broken down into their polar and disperse fractions and thus enable statements to be made about the lubrication condition and wear of sealing systems in operation.

The bubble pressure tensiometer science line t60 from SITA is a measuring system with which wetting properties such as the surface tension of fluids can be determined as a function of temperature. The wetting properties of lubricants can have a significant influence on the lubrication condition of sealing systems. Unsuitable wetting properties lead to increased wear of the sealing components during operation.

Form and geometry measuring instruments

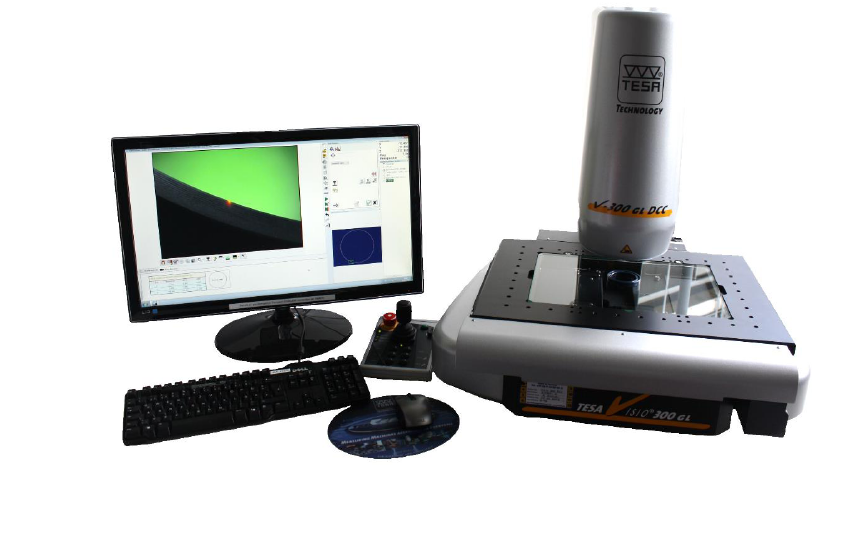

The inner diameter of a rotary shaft seal or a hydraulic rod seal can be used as a wear parameter in endurance tests. The sealing ring is optically measured contact-free with the profilometer in transmitted light. The profilometer is particularly well suited for measuring the seal ring diameter because, unlike a micrometer screw, the seal is not deformed during measurement and the measurement is automated.

The coordinate measuring machine from Carl Zeiss makes it possible to measure geometrical sizes in a measuring range of approx. 900 x 1200 x 650 mm, e.g. the diameter at the sealing edge can be determined, or sealing grooves or entire housings can be measured.

Simulation

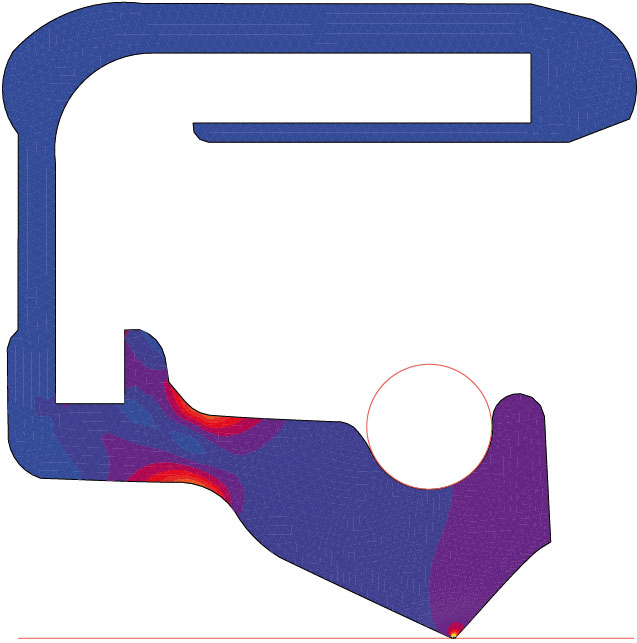

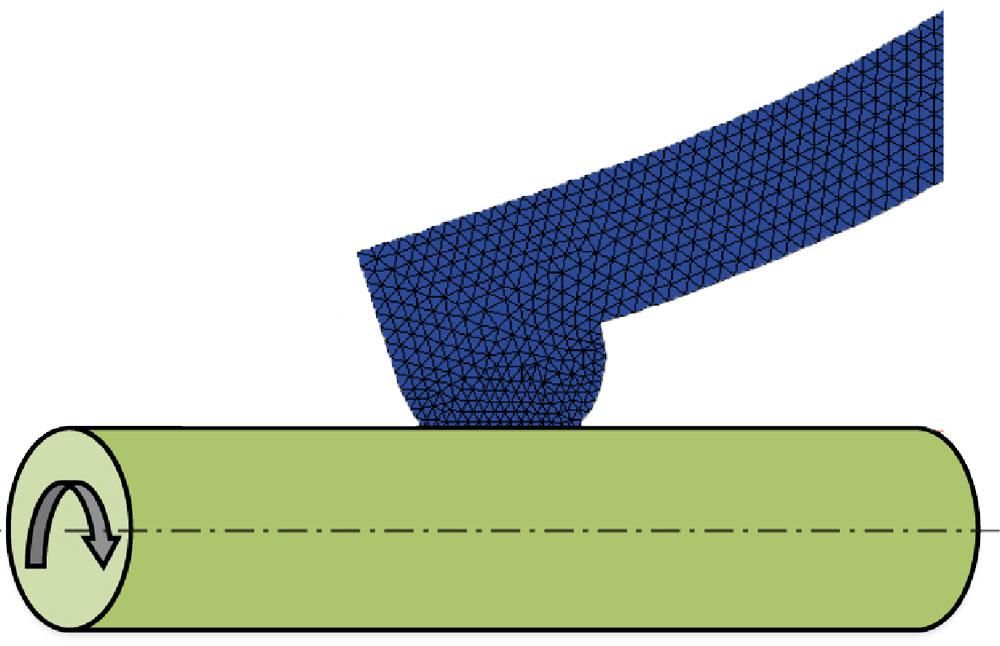

With the help of finite element simulation, it is possible to determine the stresses and deformations of seals in operation. In addition to determining pressure curves and radial forces, the deformation of the seal in operation can allow conclusions to be drawn about the function of the seal. Thus, geometry optimisations can also be carried out.

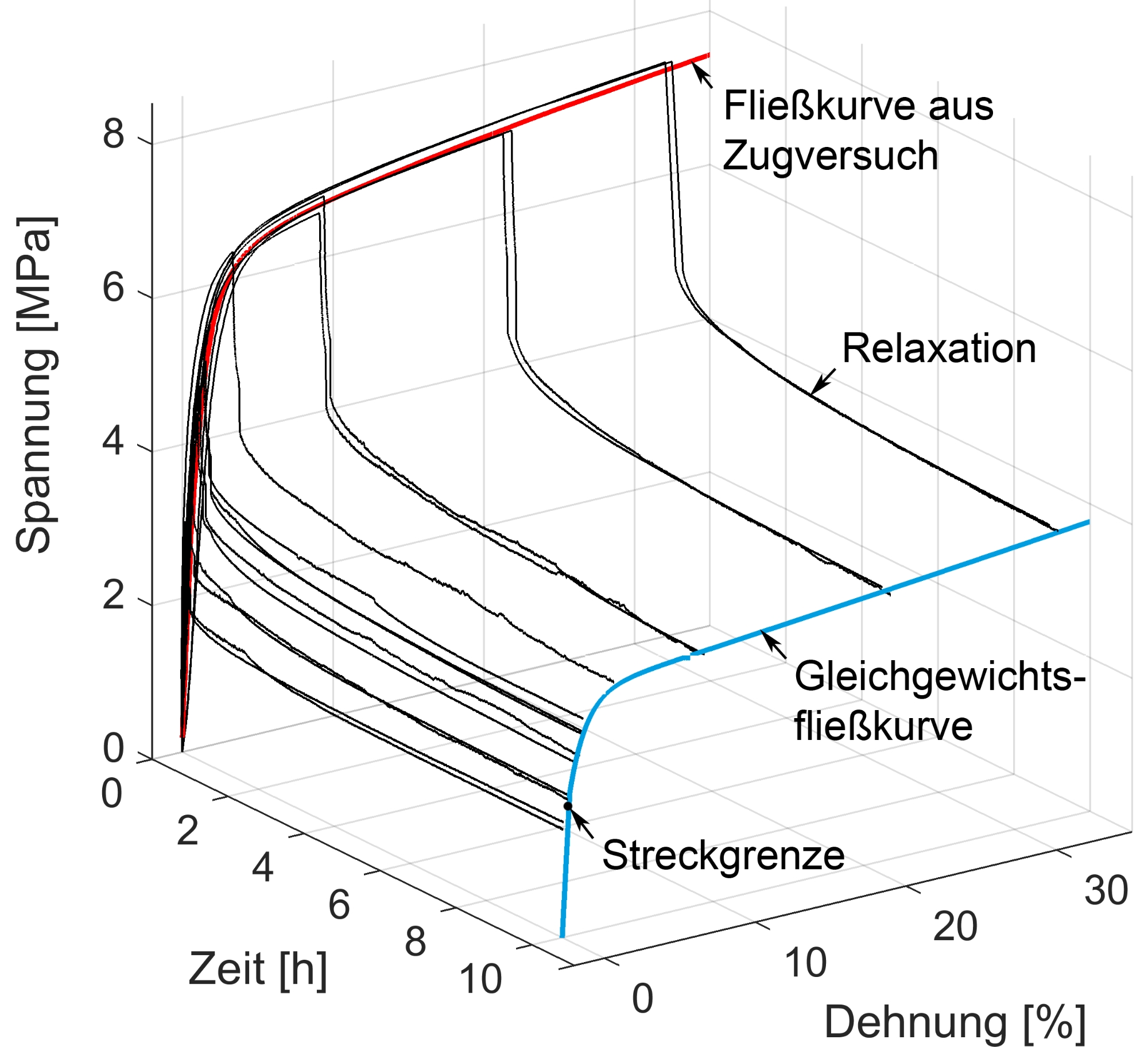

The material behavior of many sealing materials is strongly time and temperature dependent. For this reason, viscoelastic material models that describe effects such as stress relaxation and creep are frequently used in FEM simulation. The characteristic values can be determined, for example, on the institute's own universal testing machine.

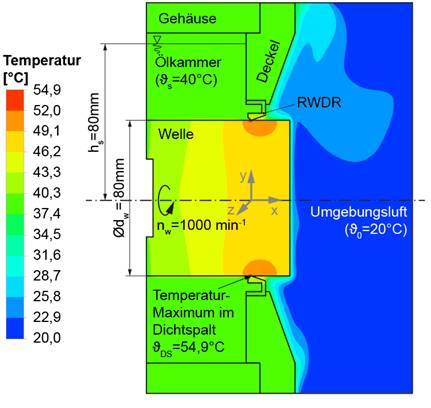

Numerical flow simulation (CFD) can be used to investigate the flow conditions in sealing systems. The CFD simulation focuses on the lubricant supply and the dissipation of frictional heat. Combined heat and flow simulation can be used to determine the temperature in the contact area of dynamic sealing systems.

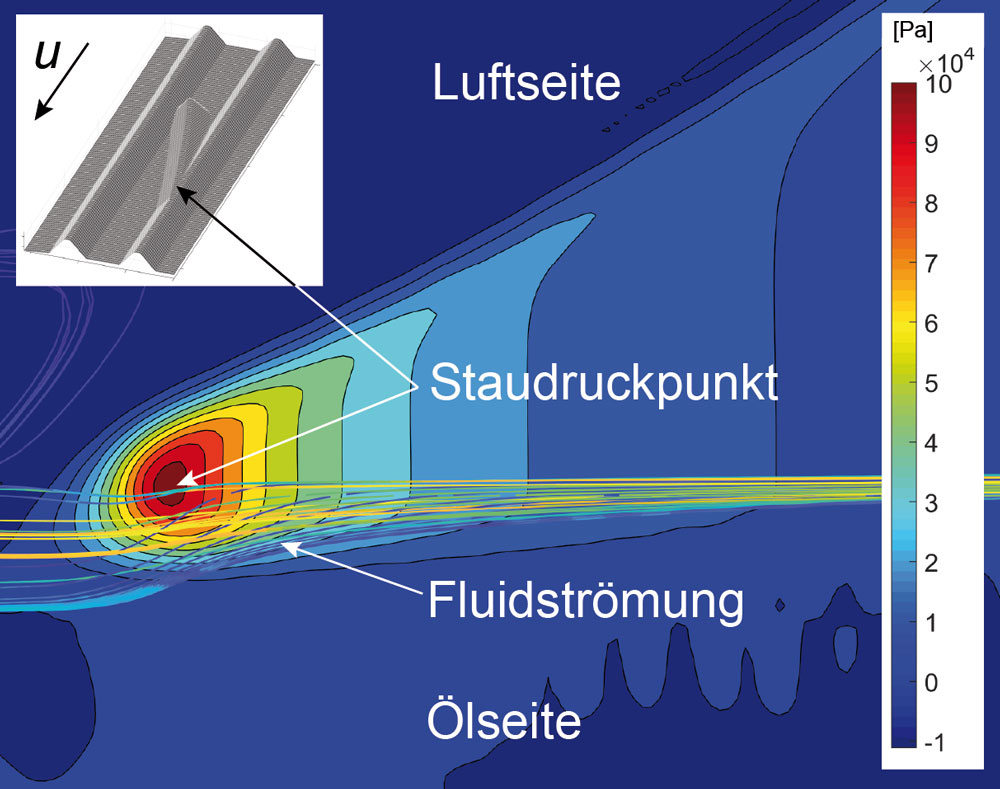

The frictional torque and the conveyance value of a dynamic seal can be analysed numerically with the help of elastohydrodynamic simulation (EHD). The basis for this is a three-dimensional geometry model of the seal in the area of the seal contact. Typical results of the EHD simulation are, for example, the hydrodynamic pressure and the hydrodynamic gap height.

The IMA-FFSim program can be used to analyze the isoviscous elastohydrodynamic lubricant film (I-EHD) structure in narrow gaps verwendet werden.

Wear severely limits the operating life of contacting sealing systems. At the Institute for Machine Elements, wear simulations with wear laws of varying complexity are carried out to investigate the progressive material removal at the sealing edge. For this purpose, the thermo-mechanical and wear-specific material parameters of the sealing elements are determined in advance in standard tests.

Combined heat and flow simulation can be used to determine the temperature in the contact area of dynamic sealing systems. This allows the influence on the temperature in the contact area to be investigated under different operating and environmental conditions such as shaft speed, fluid level, fluid temperature and material selection.

Contact Head of Sealing Technology

Frank Bauer

apl. Prof. Dr.-Ing.Head of Department