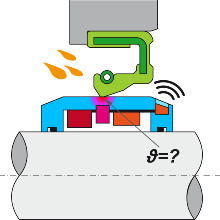

The goal of the research project is to integrate a sensor system into a shaft sleeve using 3D-MID technologies. This sensor system determines the temperature in the contact area of a shaft seal without compromising the sealing function. The measurement results are intended to be transmitted wirelessly and in real-time to an evaluation unit.

In collaboration with the Institute for Factory Automation and Production Systems (FAPS) at the Friedrich-Alexander-University in Erlangen-Nuremberg, the sensor system is conceptualized and optimized through simulation. Subsequently, prototypes and functional models with progressively increasing capabilities are manufactured and tested on a test bench.

The IGF project 22854 N/1 of the Forschungsvereinigung Räumliche Elektronische Baugruppen 3-D MID e.V is funded by the AiF as a support of the Industrielle Gemeinschaftsforschung (IGF, Industrial Collective Research) by the Federal Ministry for Economic Affairs and Climate Action (BMWK) on the basis of a decision by the German Bundestag.

Publications

- Olbrich, Christoph; Piechulek, Niklas; Feldmeth, Simon; Bauer, Frank: Determination of the contact temperature of rotary shaft seals without compromising the tribological system. Brief. — 767

- Olbrich, Christoph; Feldmeth, Simon; Piechulek, Niklas; Bauer, Frank; Jörg, Franke: Intelligente Wellen-Dichtungen mittels 3D-MID-Sensor-Integration SmartSeal. Brief. — 761

- Olbrich, Christoph; Feldmeth, Simon; Piechulek, Niklas; Bauer, Frank: SmartSeal: Monitoring system for the contact tem-perature of rotary shaft seals in operation. Brief. — 752

- Olbrich, Christoph; Bauer, Frank: Determination of the contact temperature of rotary shaft seals without compromising the tribological system. Brief. — 751

Contact

Simon Feldmeth

Dipl.-Ing. Pat.-Ing.Team Management

Christoph Olbrich

M.Sc.Research Associate