The aim of the research project is to develop and validate a kinematics model for parameter-dependent representation of the grinding process. This enables the reproducible generation of macro lead-affected and macro lead free sealing counterfaces to increase the functional reliability of rotary shaft seals subjected to high dynamic loads.

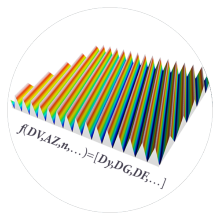

For this purpose, macro lead -determining parameters are identified and implemented in a kinematic simulation model. The resulting surfaces are compared with real surfaces of the same manufacturing parameters and evaluated.

Further process influences are added to the model in order to represent the grinding process efficiently and accurately enough. By determining grinding parameters for the production of macro lead free surfaces, the risk of leakage in rotary shaft seals can be reduced.

Publications

2022

- Haffner, Georg ; Baumann, Matthias ; Bauer, Frank: Formation of Macro Lead Using Plunge Grinding – a Kinematic Approach. In: International Sealing Conference : Fachverband Fluidtechnik im VDMA e.V., 2022. — ISBN 978-3-8163-0756-3, S. 193–209 — IMA-DT 732 (peer-review)

- Haffner, Georg ; Baumann, Matthias ; Schmuker, Stefan ; Bauer, Frank: Approach to the Description of Macro Lead Formation by Means of a Kinematics Simulation Model. In: Tribology transactions. Bd. 65, Taylor & Francis (2022), Nr. 4, S. 749–761 — IMA-DT 719 (peer-review)

Contact

Georg Haffner

M. Sc.Research Associate