Test Benches for Research and Education

(under construction)

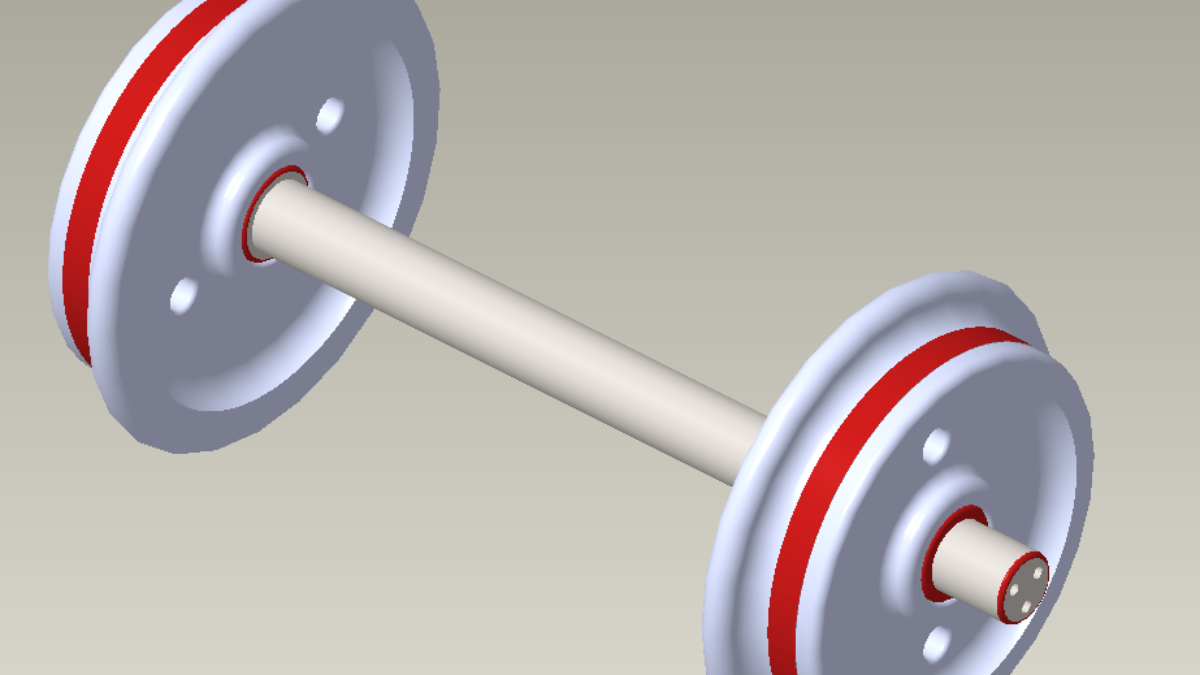

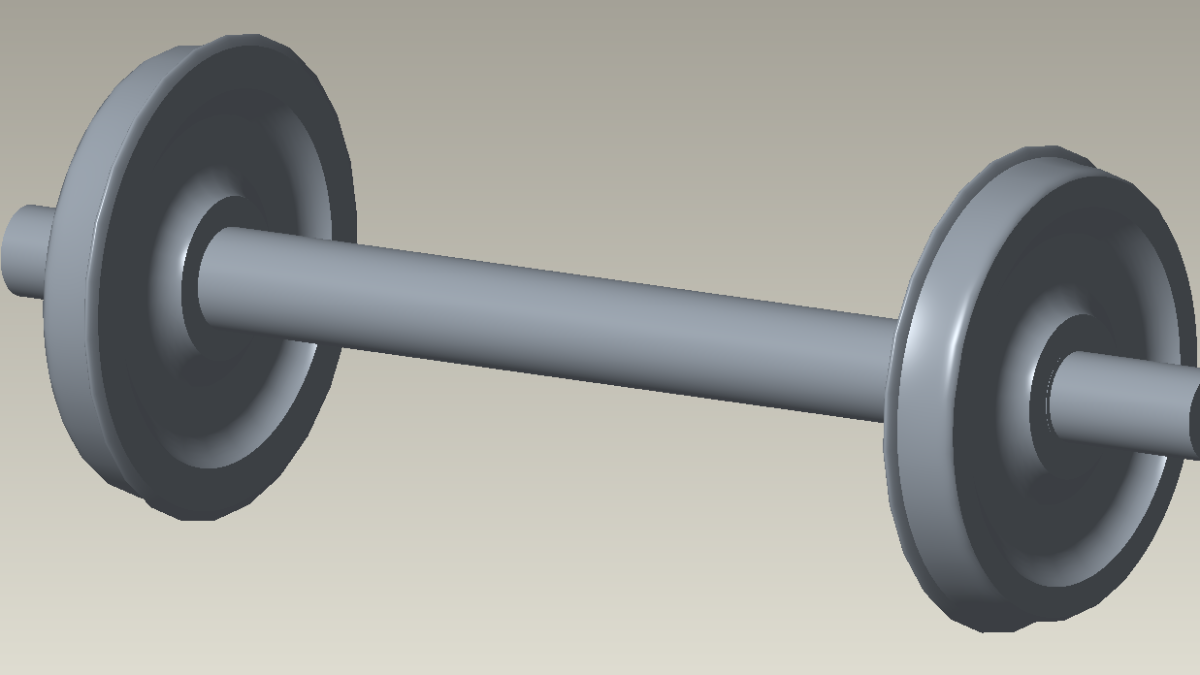

Demonstrator for Train Control Systems

With the support of Bombardier Transportation, Mannheim, a facility is being built to demonstrate how train control systems work. In the future, this will enable students to understand the monitoring of vehicle speed in the interaction of vehicle and infrastructure components by practicing on real components. For this purpose, the vehicle speed is simulated by a rotating wheelset including a wheel pulse generator, via which a PZB system receives all the data that is also transferred in reality. In the future, the system will be operated via a driver's console that is true to the original and with the support of a driving simulator.

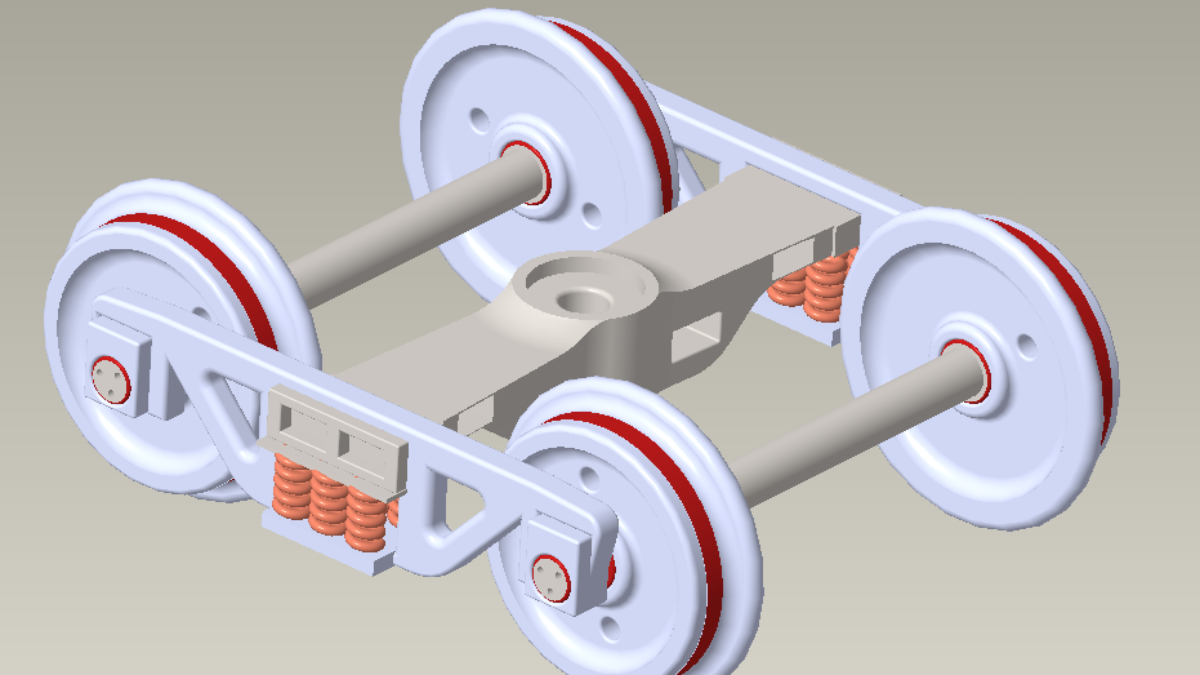

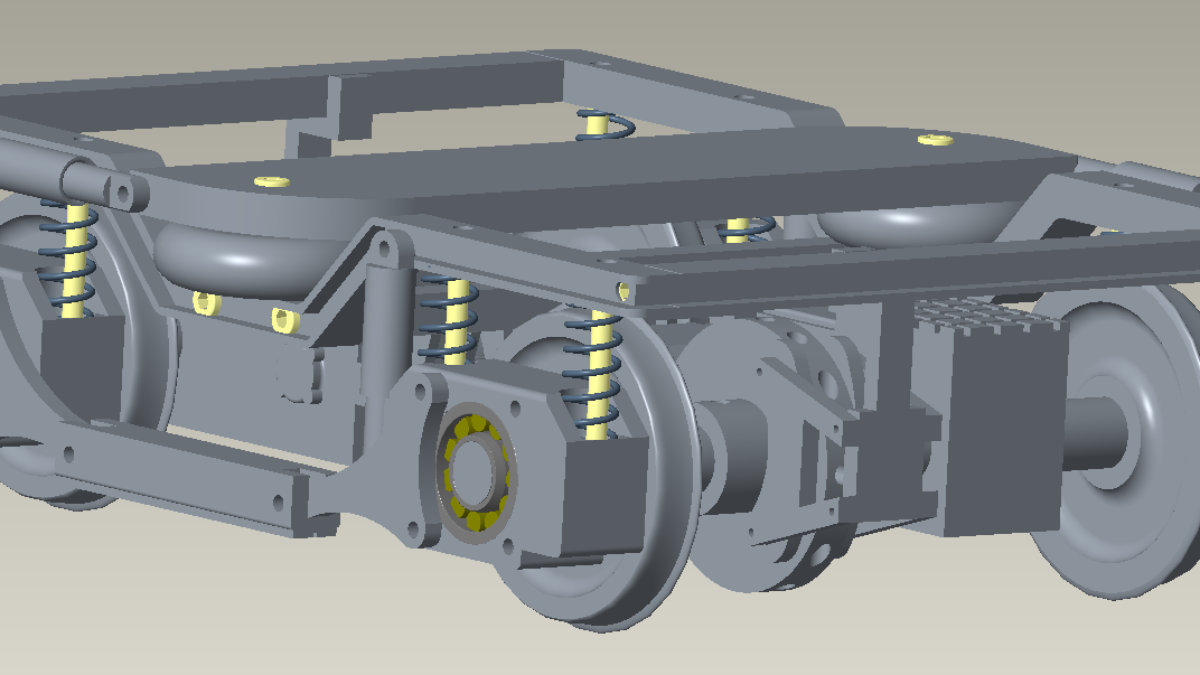

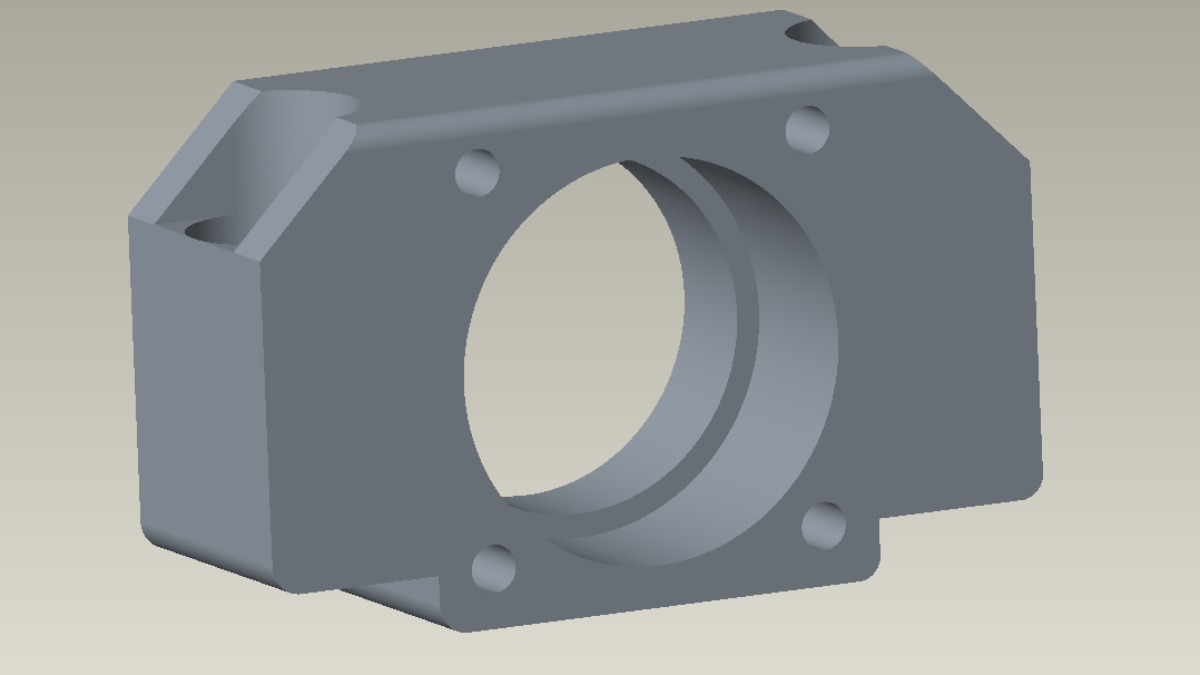

Bogie Model 1:10

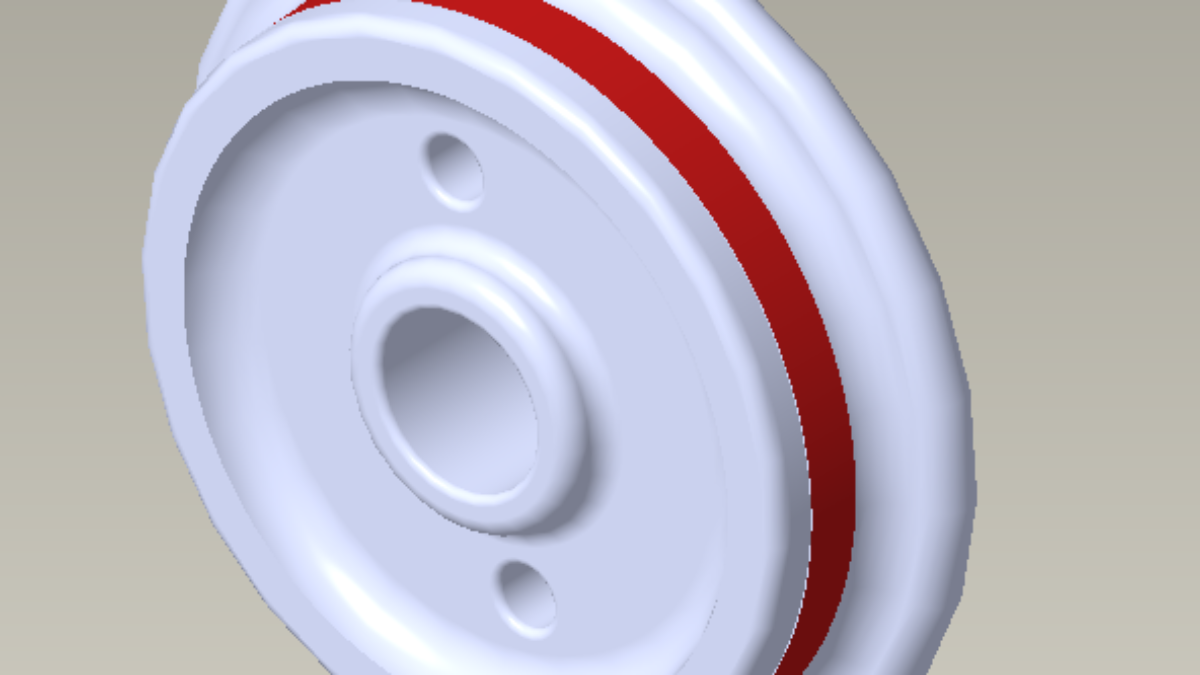

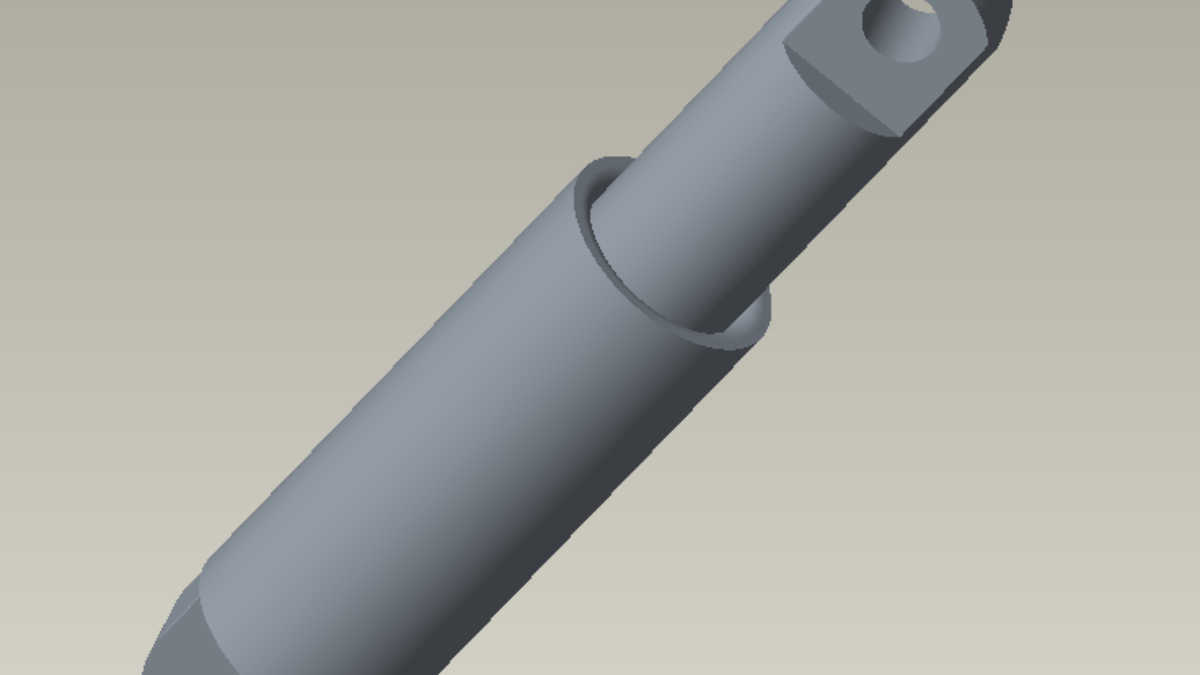

This project was started in order to better illustrate the bogie and its component to the students. The aim is to design and manufacture 1:10 bogie models as part of the internship or student work.

The bogie will first be created using CAD software and then manufactured using the conventional machining processes and 3D printing. To achieve a low weight, the parts are made of aluminum and plastic.

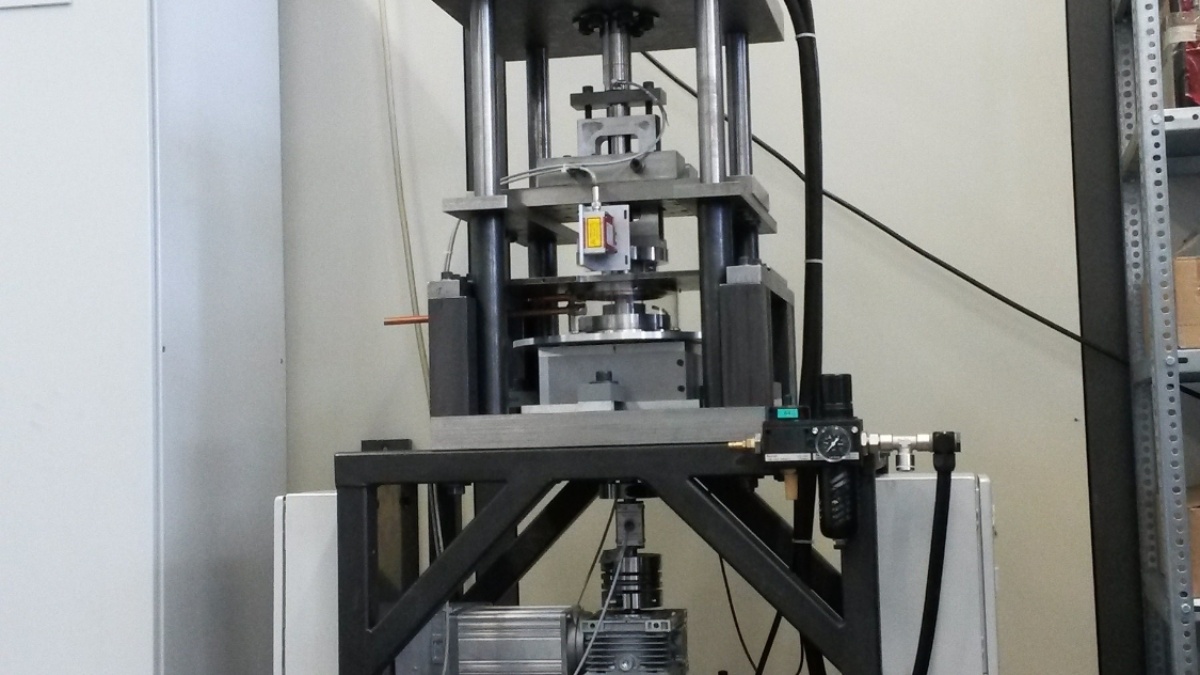

Roller Test Bench, Tribometer Test Bench (with Knorr-Bremse)

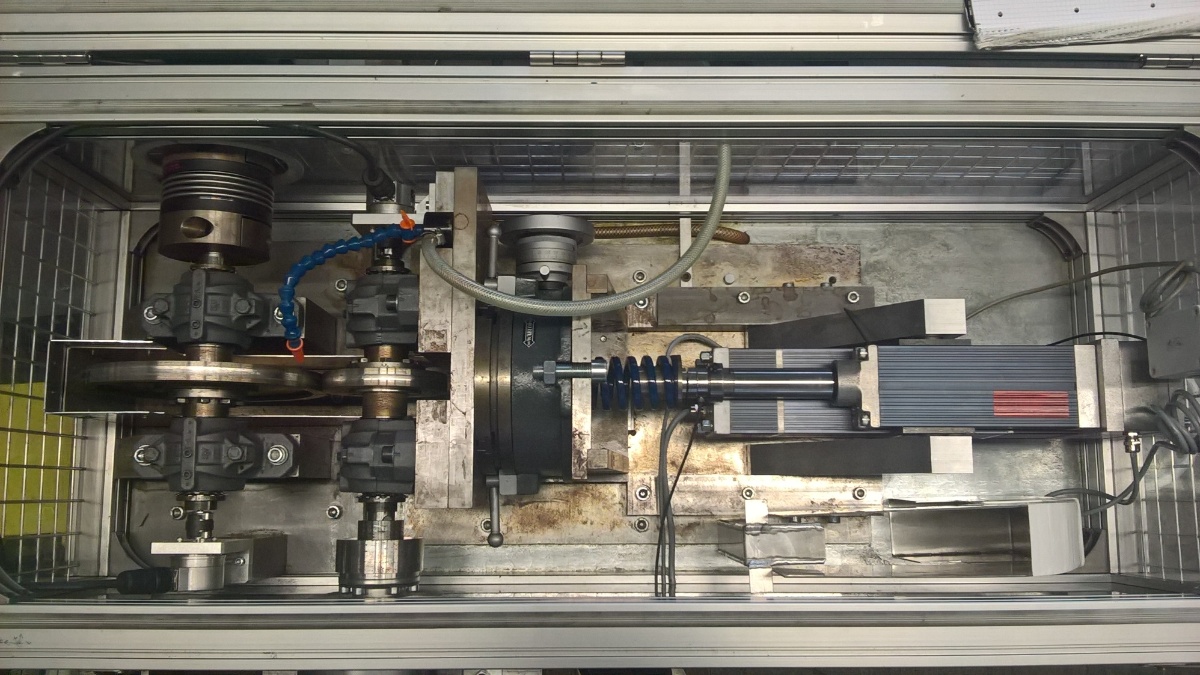

Both the roller test rig and the tribometer test rig are designed to provide in-depth knowledge of the frictional connection between wheel and rail. The roller test stand replicates on a scale of 1:10 a rail wheel rolling on a rail, which is either driven or braked. The tribometer test rig simulates the drilling friction that occurs locally, for example, when the wheel flange contacts the rail flank. To simulate different weather conditions, (thin) liquid intermediate media can be introduced into the contact point of the roller test rig and solid or viscous intermediate media into that of the tribometer test rig.

In both cases, a defined normal force is applied to determine the adhesion value. In the case of the roller test rig, the rolling of two discs with slip results in the simulated application of a traction or braking force (longitudinal force), while in the case of the tribometer test rig, simultaneous rotation of the test specimen results in a torsional stress at the contact point (drilling friction). In each case, the acting forces are recorded via the measurement technology and the adhesion values are determined from this.

Both test rigs are the property of Knorr-Bremse AG and were made available to us for scientific work.