Current projects

- Research Project: Reliability assessment of vehicles

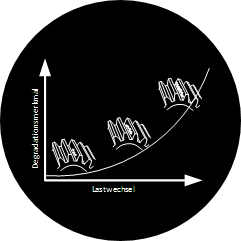

Development and evaluation of an efficient and reliable methodology for reliability assessment based on event-based endurance testing of vehicles - Research Project: Reinforcement Learning for Adaptive Operations and Maintenance Strategies

Development of an AI-Based Framework for Adaptive Operations and Maintenance Strategies Using Reinforcement Learning - Reliability assurance of safety-critical systems at CERN

Development of a guideline for the reliability assurance of safety-critical small series systems

- Cost-efficient reliability of PV power plants with battery systems

Optimizing the availability of PV power plants with battery storage by forecasting the remaining useful life and condition monitoring using integrated PHM solutions and predictive maintenance. - Safety of the intended functionality

Functional safety and safety of the intended functionality for powernets - Reliability of passive components

Reliability and lifetime model of passive components - Reliability Assurance of Variants

Effort-reduced reliability assurance in product variant development considering prior knowledge - Data-driven condition monitoring of electronic systems at CERN

Condition monitoring of electronic systems by integrating expert knowledge and hardware tests into machine learning algorithms - Reliability of Adaptive Load-Bearing Structures

Collaborative Research Centre 1244: adaptive skins and structures for the built environment of tomorrow - Lifetime Tests of HV Batteries with Prior Knowledge

Efficient planning of lifetime tests for reliability assurance of hv batteries considering prior knowledge - Lifetime Model for a Timing Belt Drive

Lifetime model for a timing belt drive in steering gears based on design of experiments (L-DoE)

Completed projects

- Lifetime Model Winding Insulation

Development of a holistic lifetime model for the winding insulation of electrical machines on the basis of the acting damage mechanisms and their different load levels

Project archive

Marcel Göldenboth

In the international market, service life and reliability are significant quality criteria for holding one's own against the competition. Especially in the cost-driven market segment of renewable energies, reliability is the key for load-oriented dimensioning with which the service life targets can be achieved in a resource-efficient way. Current approaches for the reliability assessment of electronic components are based on hypotheses that do not allow for a valid reliability analysis. In this project, therefore, a consistent methodology for the reliability analysis and validation of inverters is to be developed. The project mainly consists of the work packages: Component and device analysis, failure and aging mechanisms, development of a new method, field data analysis and the evaluation of test procedures.

Achim Benz, IMA

In the international market, service life and reliability are significant quality criteria for holding one's own against the competition. Especially in the cost-driven market segment of renewable energies, reliability is the key for load-oriented dimensioning with which the service life targets can be achieved in a resource-efficient way. Current approaches for the reliability assessment of electronic components are based on hypotheses that do not allow for a valid reliability analysis. In this project, therefore, a consistent methodology for the reliability analysis and validation of inverters is to be developed. The project mainly consists of the work packages: Component and device analysis, failure and aging mechanisms, development of a new method, field data analysis and the evaluation of test procedures.

Kim Hintz, IMA

In view of simplifying the installation of small photovoltaic systems through modular flexibility, as well as increasing their safety and efficiency, the electronic components are integrated directly into the solar module. The resulting heat generation and the associated changed general conditions, as well as the very high service life requirement of more than 20 years, make a precise analysis from a reliability point of view inevitable. The aim is to evaluate the critical changes associated with the module integration of the electronics from a reliability point of view and to ensure that the newly developed electronics solutions are also competitive with the older variants under particularly critical operating conditions directly on the solar module.

Martin Diesch, IMA

The solar inverters used in the sector of renewable energies have the function to keep the photovoltaic modules at the optimal operating point and to convert the DC voltage generated by the PV modules into AC voltage and to feed this into the public grid. The inverters can be used both outdoors and indoors, as well as in a wide variety of different climatic conditions. Humidity and temperature are key factors in the failure of electronic components. This stress leads directly to damage of the inverter's components. In many cases, temperatures are calculated by corresponding sensor equipment and models. However, the permeation of moisture into the inverter is usually not recorded. The objective is therefore to characterize the moisture inside the inverter by means of suitable models. The load on the components caused by the humidity will thus be characterized and taken into account for the development of new product developments.

Alexander Grundler, IMA

Today's products are equipped with a wide range of functions and components. This enables the necessary competitiveness in times of digitalization, but also causes a large number of potential system failure causes. The validation of such systems and especially the demonstration of system reliability is a challenge. With available prior knowledge, an efficient validation strategy can be achieved by combining different test types and different test levels, such as system, subsystem, component and unit tests, using the concept of Probability of Test Success and Bayes' theorem. In doing so, the available information is used comprehensively and according to its quality for planning the validation tests.

Armin Köhler, in Cooperation with Robert Bosch GmbH

Driven by the global megatrends such as electrification and automation, the automotive industry is developing strongly in technical and innovative fields. In particular, the working area of driver assistance systems and automated driving functions are current fields of innovation. Most of these systems have one thing in common: they are electrical and/or electronic (E/E) systems that are responsible for the safety of drivers and passengers. The basis of the functionality is always the sufficient power supply of these safety-relevant systems. This increases the safety relevance of on-board power systems (powernets) and associated components enormously. For this reason, the entire power supply system must be developed and verified in accordance with functional safety standards. In the field of road vehicles, the functional safety process according to ISO 26262 must be applied.

Philipp Kilian, in Cooperation with Robert Bosch GmbH

Innovative and holistic safety concepts for the power supply system are required due to the megatrends electrification, automation and connectivity. To cope with these trends and to be able to react dynamic on changing requirements, the corresponding safety concepts shall be structured in a modular and scalable manner. Therefore, we do research on innovative approaches to automatically derive efficient safety concepts including their validation and verification based on artificial intelligence and/or optimization algorithms. Because the evaluation of different hardware-architecture is very time consuming and error prone, we want to investigate an automated approach based on fault injection to evaluate hardware building blocks in a modular way. The fault injection shall be based on generic fault models to enable automation and increase objectivity.

Tamer Tevetoglu, IMA

As part of a predictive diagnostic model, the Future Load Model is being used to predict future loads (time series data) that significantly influence the remaining lifetime of the lead-acid battery. For this purpose, past sensor data of the battery are first stored and grouped into representative load cases using unsupervised machine learning methods. Then, a feedback neural network (RNN) based on a so-called long short-term memory (LSTM) is trained and being used to predict future signal data. The now predicted data is assigned to the representative load cases by a classifier, e.g. Random Forest. By using the scattering of the data points within a load case, the confidence intervals of the predicted signal data are derived. Now the remaining lifetime can be calculated based on the future loads.

Frank Müller, DFG

With stochastic modelling techniques, it is possible to model complex, technical systems and to simulate their reliability and availability. At the moment, the statistical quality of the initial data cannot be considered within the analysis. Objective of the research project is the continuously consideration of the statistical quality of the input data within the analysis method, in order to combine the expressiveness of confidence intervals with the performance of the modelling techniques.

Martin Diesch, MTU Friedrichshafen GmbH

Methods and technologies for fail-safe adaptive bearing structures and their elements and structures

Andreas Ostertag, DFG Sonderforschungsbereich (SFB 1244)

In the SFB 1244 the aspired adaptive structures need to adapt to the current load situation like wind and weather and the user. Beside of guaranteeing a high reliability the behavior of the system when it comes to a failure is very important. The objective is to have a Fail-Safe-concept managing an adaptive fault response which keeps the operating condition sustainable as far and as long as possible. Furthermore supporting Fail-Safe-elements will be developed and applied.

In the SFB 1244 the aspired adaptive structures need to adapt to the current load situation like wind and weather and the user. Beside of guaranteeing a high reliability the behavior of the system when it comes to a failure is very important. The objective is to have a Fail-Safe-concept managing an adaptive fault response which keeps the operating condition sustainable as far and as long as possible. Furthermore supporting Fail-Safe-elements will be developed and applied.

Andreas Kroner, Daimler AG

Thomas Herzig, IMA

The testing effort required to prove the reliability target can already be taken into account in the early development process. The aim is to achieve an optimum between product development costs (material, production, ...) and testing costs (test type, number of test items, ...) by adjusting the overdimensioning. (material, production, ...) and testing costs (type of test, number of test items, number of test rigs required, choice of load levels in accelerated testing, ...). The choice of the appropriate testing strategy is thereby objectively evaluated with the help of test costs, total time and probability of success and is influenced by the oversizing of individual failure mechanisms considered in the development process.

The testing effort required to prove the reliability target can already be taken into account in the early development process. The aim is to achieve an optimum between product development costs (material, production, ...) and testing costs (test type, number of test items, ...) by adjusting the overdimensioning. (material, production, ...) and testing costs (type of test, number of test items, number of test rigs required, choice of load levels in accelerated testing, ...). The choice of the appropriate testing strategy is thereby objectively evaluated with the help of test costs, total time and probability of success and is influenced by the oversizing of individual failure mechanisms considered in the development process.

Mark Henß, IMA

The use of machine learning enables automatic recognition of relevant patterns and trends in data that are difficult to access for humans. Missing training data, labels and a low data quality are obstacles for implementation. This project investigates how prior knowledge can be implemented in the algorithms to eliminate these deficits.

Alexander Kremer, Walther Flender GmbH

Kevin Lucan und Mark Henß, Bergische Achsen, DAF, Daimler, Haldex, IVECO, Knorr-Bremse, MAN, MERITOR, SAF Holland, WABCO

Frank Müller und Jan Gröber, Festo AG & Co. KG

Julian Popp, HSA Aalen, ISSA Forschungsprojekt

The demand for raw materials from the deep sea is constantly increasing. In order to extract these raw materials, systems are needed that are environmentally friendly, safe, reliable and also available. The project will develop a system architecture with a focus on mechatronic drive technology that meets the enormous requirements that prevail in the deep sea. Verification and validation on a self-developed test bed environment is also part of the project.

The demand for raw materials from the deep sea is constantly increasing. In order to extract these raw materials, systems are needed that are environmentally friendly, safe, reliable and also available. The project will develop a system architecture with a focus on mechatronic drive technology that meets the enormous requirements that prevail in the deep sea. Verification and validation on a self-developed test bed environment is also part of the project.

Volker Schramm, CERN

Analysis of surveillance systems for particle accelerators to improve the reliability, availability and the protective function. Development of a methodology on how to design, produce, test and operate dependable electronic systems. In addition, application of the methodology for the system reliability analysis, definition of the operational strategy and execution of functional and reliability tests.

Analysis of surveillance systems for particle accelerators to improve the reliability, availability and the protective function. Development of a methodology on how to design, produce, test and operate dependable electronic systems. In addition, application of the methodology for the system reliability analysis, definition of the operational strategy and execution of functional and reliability tests.

Sebastian Imle, WITTENSTEIN motion control GmbH

The extraction of raw materials in the deep sea requires an environmentally friendly and safe propulsion solution. The system architecture defines the components and interfaces of the system in terms of type and quality. The processing quality of this information via a secure communication architecture determines the diagnostic coverage and functional safety of the system. The design of a condition monitoring system for use in the deep sea is the goal of this project.

Alexander Grundler, Martin Dazer; Daimler AG

Alexander Grundler, ZF Friedrichshafen AG

Frederic Heidinger, Patrick Münzing and Andreas Ostertag, Robert Bosch GmbH

Fei Long, GSaME, DFG

Zeljana Beslic, IMA

Sebastian Held, Knorr-Bremse Systeme für Nutzfahrzeuge GmbH

Martin Dazer, Knorr-Bremse Systeme für Nutzfahrzeuge GmbH

Contact Head of Reliability Engineering

Martin Dazer

PD Dr.-Ing.Head of Department

Paula Fischer

M.Sc.Vice Head of Department